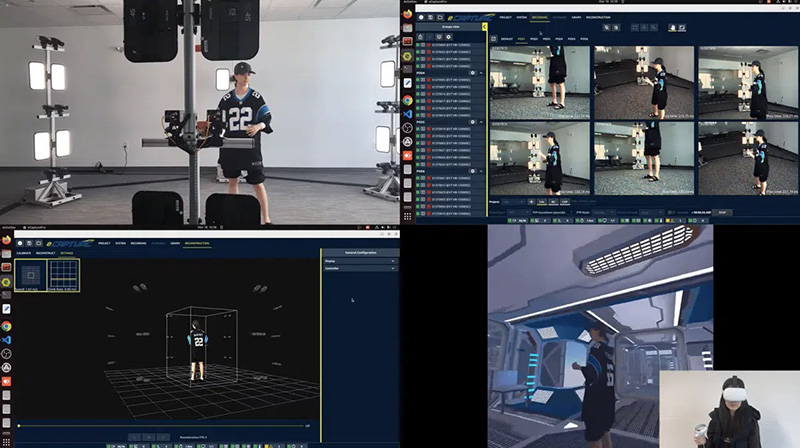

The combined 2D/3D surface inspection by IMS was installed for the first time in a pickling plant in November 2021 at Thyssenkrupp Rasselstein in Andernach, the world’s largest production site for packaging steel. At Thyssenkrupp Rasselstein, pickling is the first processing stage of the hot strip on its way to black plates with thicknesses of 0.100 to 0.499 mm. The system’s 3D channel uses laser triangulation to detect serious defects such as shells, holes and creases, which can lead to strip tears or roller damage in the subsequent process. Due to the automatic depth measurement of the defects, they can be clearly identified and evaluated. In addition, the integrated 2D channel detects surface defects without height information, such as residual scale.