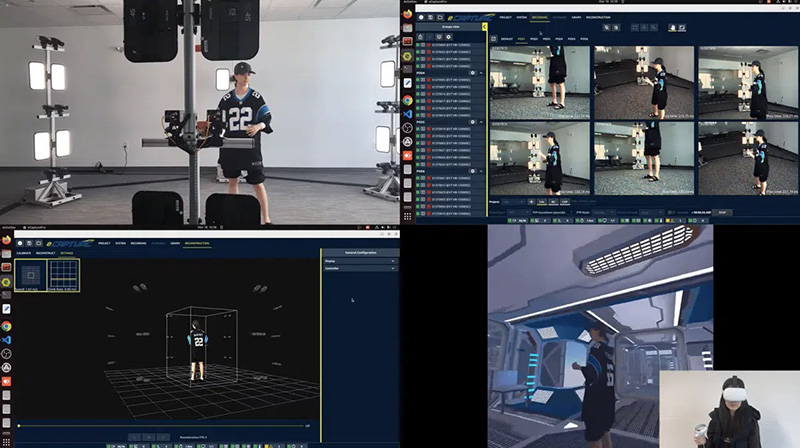

For the 3D measurement of chassis springs, Qsigma has developed a measuring system equipped with laser scanners by Micro-Epsilon. The Spring Measurement System is used for automatic spring detection, evaluation of the wire contour and determination of the wire diameter.

In the compact measuring cell, the spring to be tested rotates on a longitudinal axis. During the rotation, a laser scanner by Micro-Epsilon is moved over the spring by two linear axes in horizontal and vertical direction. To achieve the highest accuracy, the sensors are optimally positioned in the process by algorithms developed by Qsigma. The laser scanner transmits the generated individual profiles to a computer via a Gigabit Ethernet interface. The computer converts the data into a 3D point cloud, outputs it via a display and enables further processing in the production machines via M2M integration.