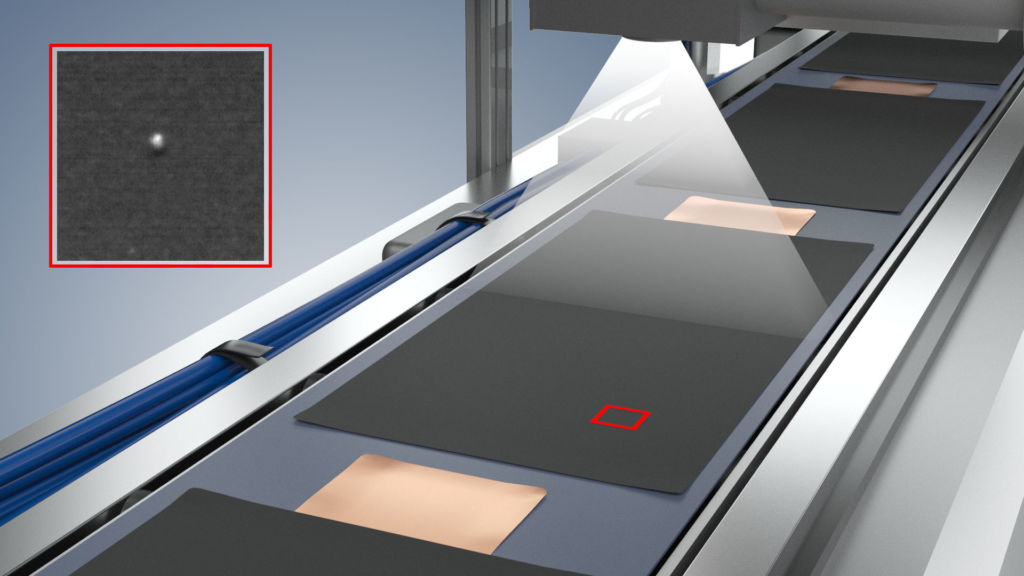

A new inline process by Vitronic enables quality testing of lithium-ion batteries for electric vehicles. It can be used to detect particle contamination in battery cells as well as other defects. A high-resolution 16K line scan camera sensor simultaneously takes multiple images of the electrode foils from different angles, with different illumination. The detected particles are measured and automatically classified. Other defects can also be detected, such as position deviations, edge and cut defects, or surface properties of the electrodes that have changed due to transport.