The PS-30 profile sensor by Di-Soric is ready for use in just a few steps. Up to ten target profiles simplify the inspection and measurement of changing objects on the same production line. Using the light-sectioning method, the sensor detects profiles of objects and recognizes differences as small as 0.5mm. The inspection area can be narrowed down to relevant sections thanks to the ROI function. Two green markers visualize the selected ROI on the laser line.

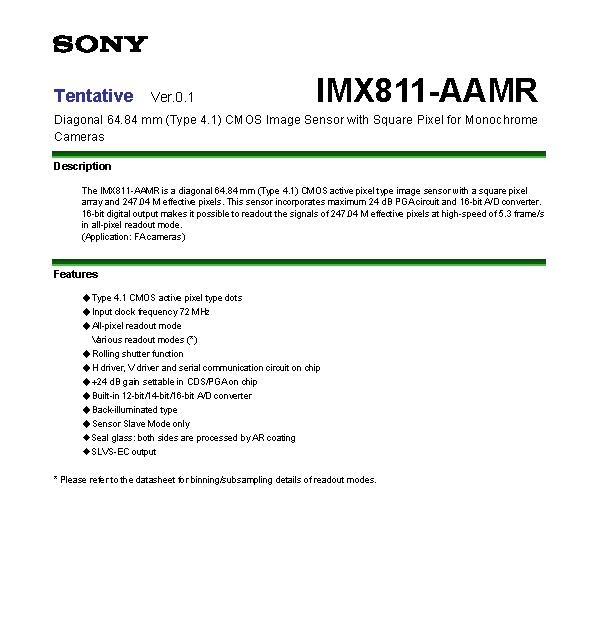

247MP CMOS by Sony

Sony recently released a 247MP rolling shutter CMOS image sensor available in monochrome (IMX811-AAMR) and color (IMX811-AAQR) variants which have a 64.84mm diagonal, a square pixel array, as well as 5.3fps.