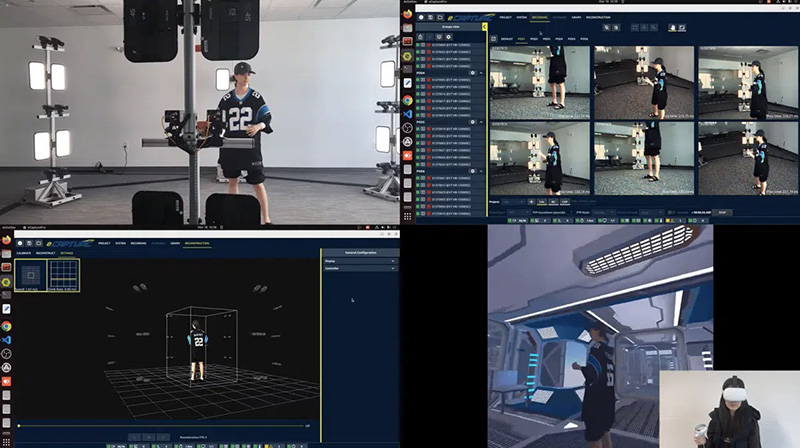

With the CAD-based visual inspection system CAD2SCAN, areas of multi-layered components to be inspected can be defined directly in the CAD model, inspection plans can be optimized, and time-consuming inspections can be automated, thus reducing inspection time. In addition, because multiple inspection points can be captured in a single image, cycle time can be reduced. In combination with Kitov’s Smart Visual Inspection and Review Station modules, the system offers various visual inspection options. This can be demonstrated especially on components with complex 3D geometry and complicated inspection requirements. For robot-based visual inspection, the tool automatically takes all available information, including geometry and component specifications, from CAD. Using this data, the software calculates the best viewing and illumination angles for each specific feature. Subsequently, the acquired surface data is exported to the Kitov Planner tool and a 3D model of the component to be inspected is generated.