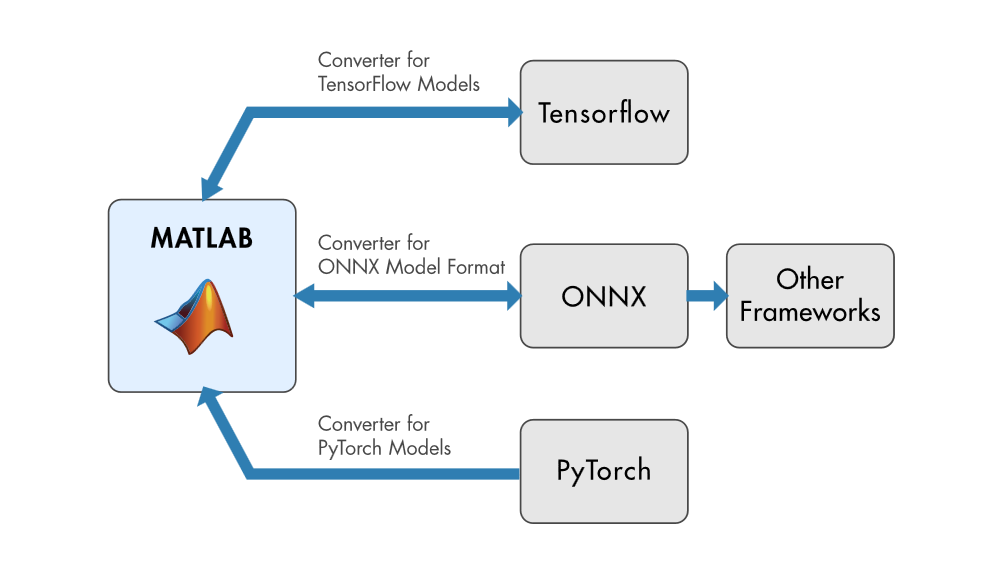

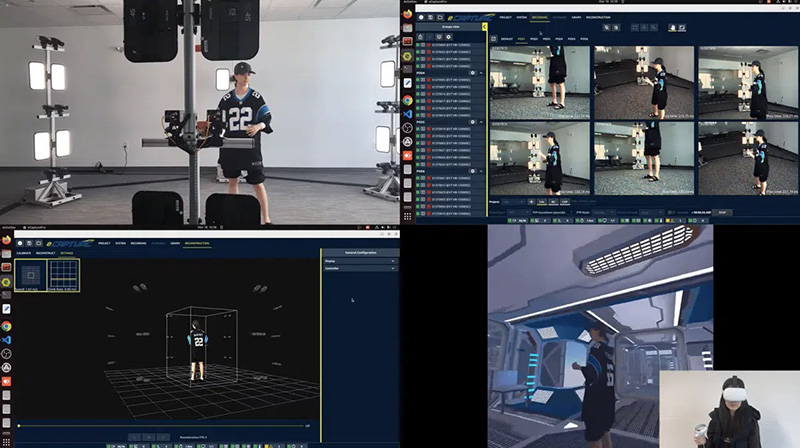

In the production of additively manufactured components using fused filament fabrication (FFF), thermography has great potential due to the combination of measuring the filament temperature and large-area imaging of the printed object. Therefore, SKZ is developing an inline measurement technique based on passive thermography, which allows a permanent control of the components. Tests showed that specifically generated defect features can be reliably detected in the recorded temperature curves. Classic defect features such as under-extrusion or poor layer adhesion can be clearly distinguished from the reference layers by deviations in the cooling curves. The video sequences were recorded using cameras by Optris. The generated measurement data can be divided into defect and defect-free areas using classical evaluation algorithms and thus form the basis of a data set for training a neural network. This enables classification into IO and NIO objects.