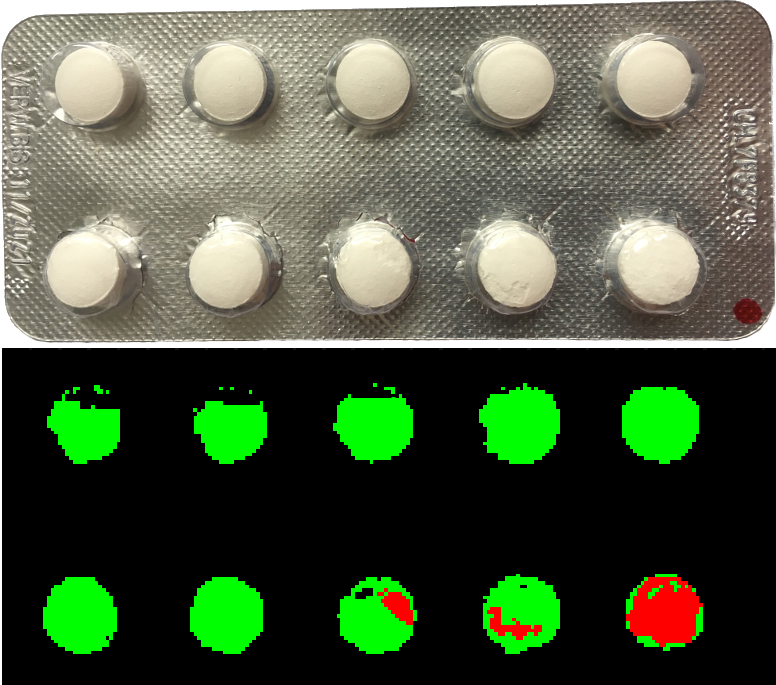

Fault detection in the pharmaceutical industry

As in many other areas, production speeds in the pharmaceutical industry are increasing rapidly worldwide. In order to reduce the risk of product recalls and to protect consumers from contaminated drugs, particularly strict safety regulations apply in this industry. Image processing systems have therefore been state of the art in the manufacturing processes of pharmaceutical products for some time in order to evaluate products in real time according to criteria such as shape, size or weight. However, the use of hyperspectral imaging and CCI systems can further optimize the monitoring of pharmaceutical production processes: Pharmaceuticals can be 100% examined for their molecular properties. A typical application of HSI systems in the pharmaceutical industry is the checking of retard tablets for correct coating. This form of medication releases the active ingredient after its administration over a longer period of time or to a specific target in the body. The sustained release coating of the tablet is decisive for this controlled release of the active ingredient: if it is damaged or missing completely, the medication gets into the body faster than desired and fails to deliver its long-term effect. With a combination of HSI and CCI technology, the quality of retard based medication can be reliably controlled, explains Markus Burgstaller: “With a hyperspectral camera working in the NIR area and the use of chemical color imaging technology with our software suite Perception STUDIO we were able to clearly demonstrate that previously artificially generated coating defects can be recognized with 100 % certainty and also in real time in high-speed production. ”This quality check is possible even through blister packs, provided the blister material is not made of aluminum, which would reflect the NIR radiation. According to Burgstaller, testing retard coatings is just one of many possible use cases for HSI technology in the pharmaceutical industry. It can also be used to reliably check whether the correct number of tablets are packed in blisters, whether they are undamaged and free from any contamination, whether the correct ingredients are contained in drug capsules or whether they are completely sealed. “Hyperspectral imaging offers numerous application options in the pharmaceutical sector and thus increases safety for patients and manufacturers.”

More security in food production

Similar guidelines as in the pharmaceutical industry apply in the production of food: In order to exclude health risks to consumers, no contamination must remain undetected in the products. The food must also contain exactly the ingredients that the manufacturer wants to and that are defined in the product descriptions for the consumer. HSI and CCI also offer numerous application options for this industry. These techniques make it easier to find any contamination in food and identify unwanted objects such as stones or earth when sorting potatoes, carrots or other vegetables, as well as shell parts or other substances in the production of nuts, even in high-speed production lines. If food is stored for too long, maggots can also nest or fresh fruit can start to rot, according to Burgstaller: “In food production, the task very often not only means to detect any contamination, but also to identify rotten, immature or pest or mold infected goods. These and many other quality defects can be safely ruled out by the use of hyperspectral imaging systems.” Industrially manufactured food such as sausage and cheese are usually offered for sale in a shrink-wrap form. Similar to the pharmaceutical industry, HSI systems also allow quality checks through the packaging in many cases. A special task here is the inspection of heat-sealed joints, which are supposed to guarantee absolutely tight packaging of the food. Even the smallest contamination or damage to these sealed joints can lead to leaky packaging and spoilage of the goods before the calculated best before date. Unsellable products or expensive product recalls would then be possible consequences for manufacturers in this area, which can be avoided in many cases by using hyperspectral imaging.