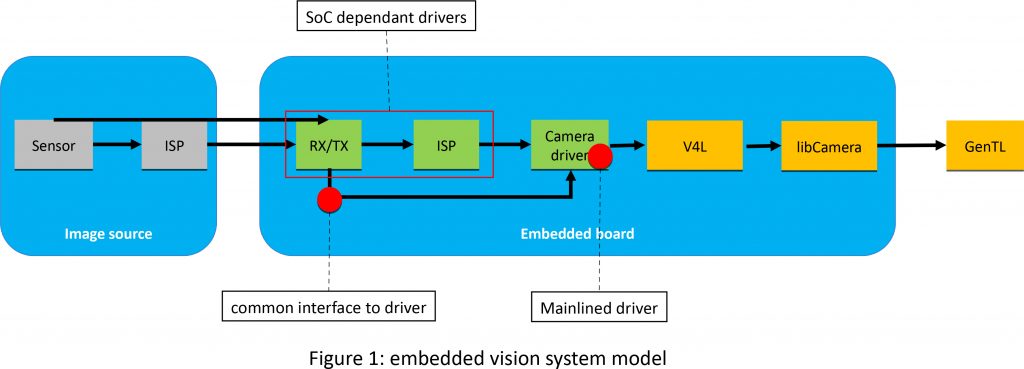

With an impressive support from companies of the machine vision industry, the standardization group currently develops a standard to achieve easy integration and exchange of different embedded cameras within embedded vision applications. The goal of this new standard which was named Embedded Vision Interface Standard (emVision) is to provide a framework which enables an easy usage of embedded vision systems for industrial solutions. In the industrial machine vision world GenCam has become the backbone which most hardware interface standards refer to. Therefore, another mandatory goal in developing the emVision standard is to give embedded system designers access to GenCam. This can be achieved on different levels. One of them is the driver framework. Here, the standardization initiative targets to establish reusable drivers for various hardware interfaces that can be configurated for devices (mainly cameras). Those drivers can/should be part of the mainline kernel to ease setup and enhance usability for the customer. The second level which is addressed by the emVision standard initiative is the user interface. Here, the standard aims to create domain specific user levels. The current focus is on V4L as a simple user interface and enhancement by connecting to GenCam – GenTL, in order to enable a ´feature set´ complexity. Mapping between the user interface levels should be ensured by presenting a V4L Transport Layer as part of the standard. The next step within the emVision working group is to finalize a white paper and to identify a first release candidate later this year. The current working group members of the emVision standard initiative include Adimec, Allied Vision, Alysium, Aval Data, Basler, Baumer, Euresys, Flir, Framos, Matrix Vision, Pleora, and Sony Semiconductor Solutions. Interested parties are welcomed to join the working group.